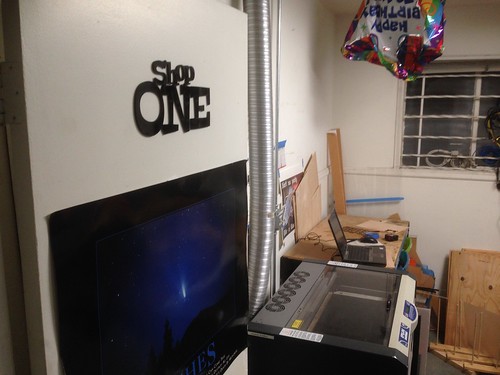

Crashspace has been hosting a number of Instructables Build Nights lately, in which we’re sent a package of new tools or technologies to play with and use for making tutorials for the Instructables site. They get advertising and a greater project presence online, we get to host free events with the latest stuff. It’s fun.

For November, we did a Build Night using the new(ish) Spark.io technology, including Spark Cores and their not-currently-available Internet Buttons. The basic gist is that they’re wifi-enabled microcontrollers that hook up to their cloud and let you do “Internet of Things” projects. Think toaster that prints the weather forecast on your breakfast. As it’s a fairly new product, there are still glitches, so it was a bit of a slog to get them working. But that means that we’ve put together more detailed instructions for starting out.

For November, we did a Build Night using the new(ish) Spark.io technology, including Spark Cores and their not-currently-available Internet Buttons. The basic gist is that they’re wifi-enabled microcontrollers that hook up to their cloud and let you do “Internet of Things” projects. Think toaster that prints the weather forecast on your breakfast. As it’s a fairly new product, there are still glitches, so it was a bit of a slog to get them working. But that means that we’ve put together more detailed instructions for starting out.

I am systematically attacking all of the tools and media available at Crashspace, in my perennial quest for world domination generalist maker skills. For the last few months I’ve been buried largely in the 3d printers and 3d modeling software. For many reasons, I’ve focused largely on Autodesk’s 123D Design (and a bit of Blender), and most of the things I print are my own designs. I like the mix of virtual and physical, and I like spending time with my beloved calipers.

In any case, I posted an instructable for a couple 3d printed diffusers I designed and printed for the Spark.io Build Night. They were a hit. The instructable shows how to make the model that I did, but the real aim is to show how to design a case/diffuser for a different device.

Another recent project is creation of a hybrid car badge for the limited release Rav4 Toyota/Tesla collaboration. The modeling stage is done, it’s been printed, acetone vapor bathed, and made smooth with a sandable primer, and I’m currently in the middle of an education on molding and chrome plating.

Soon, I’ll be posting a new tutorial for a Chibitronics Papercut Bookmark that I made for my dad for Christmas.

It’s Tuesday again, which means a new video. In this one, I recreate a 3d printed device I made for a previous Halloween costume, about 2/3 size and printed with stainless steel filament. It is a poking device mounted on a scissor mechanism. I mean, really, why not?

It’s Tuesday again, which means a new video. In this one, I recreate a 3d printed device I made for a previous Halloween costume, about 2/3 size and printed with stainless steel filament. It is a poking device mounted on a scissor mechanism. I mean, really, why not?